In recent years, there has been a significant shift in the food packaging industry towards more sustainable and environmentally friendly materials. Polylactic acid (PLA) has emerged as a popular choice due to its biodegradability and versatility. With the rise of 3D printing technology, PLA filament is being used to create innovative food packaging solutions. However, concerns about the safety of PLA products have also surfaced. This article aims to delve into the safety aspects of PLA, particularly in the context of food packaging. We will explore the composition of PLA, its applications in the food industry, and how it can be managed safely using modern food safety systems.

What is PLA?

Understanding the PLA Filament

Polylactic acid (PLA) is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. It is commonly used in various industries, including food packaging, medical implants, and 3D printing. The PLA filament, specifically used for 3D printing, has gained traction as a sustainable alternative for creating food packaging materials. When heated, this filament can be shaped into intricate designs, making it ideal for customizing packaging solutions.

PLA filament properties:

| Property | Description |

|---|---|

| Biodegradability | Capable of breaking down into natural compounds |

| Renewable sourcing | Derived from plant-based materials |

| Versatility | Can be molded into different shapes and structures |

| Temperature sensitivity | May deform at high temperatures |

What is PLA Made Of?

PLA is composed of renewable resources, primarily corn starch or sugarcane. Through a process of fermentation and polymerization, lactic acid is produced, which serves as the building block for PLA. This organic origin makes PLA an attractive option for those seeking sustainable alternatives to traditional plastics. Its biodegradability and non-toxic nature further contribute to its appeal as a material for food packaging.

PLA composition:

- Corn starch or sugarcane as primary sources;

- Lactic acid as the fundamental building block;

- Biodegradable and non-toxic properties.

Is PLA Food-Safe?

The safety of PLA in food packaging is a critical consideration. PLA is known for being non-toxic, non-allergenic, and environmentally friendly. It does not typically pose health risks when used appropriately. However, it is essential to note that PLA is sensitive to very high temperatures, which can lead to deformation. As a result, it is recommended for use with prepackaged foods that are not hot, ensuring that the packaging maintains its structural integrity.

Key points to consider regarding PLA safety:

- Non-toxic and non-allergenic nature;

- Sensitive to high temperatures;

- Suitable for prepackaged foods that are not hot.

How is PLA Used in the Food Industry?

The applications of PLA in the food industry are diverse and continue to expand. From packaging materials to disposable tableware, PLA offers a sustainable and innovative alternative to traditional plastics. Its versatility and environmentally friendly nature make it an attractive choice for businesses aiming to reduce their environmental footprint.

Applications of PLA in the Food Sector

- Packaging Materials: PLA is used to create various types of packaging, including containers, cups, and trays, providing a sustainable option for storing and transporting food products;

- Disposable Tableware: Cutlery, plates, and straws made from PLA offer a biodegradable and eco-friendly alternative to conventional plastic utensils, reducing environmental impact;

- Customized Designs: 3D printing with PLA filament allows for the creation of customized packaging designs, catering to specific food products and branding requirements.

The expansion of PLA’s applications in the food sector reflects a growing emphasis on environmental responsibility and the pursuit of more sustainable practices within the industry.

How Can You Manage Safe PLA Packaging with FoodDocs?

Temperature Log to Ensure Appropriate PLA Packaging

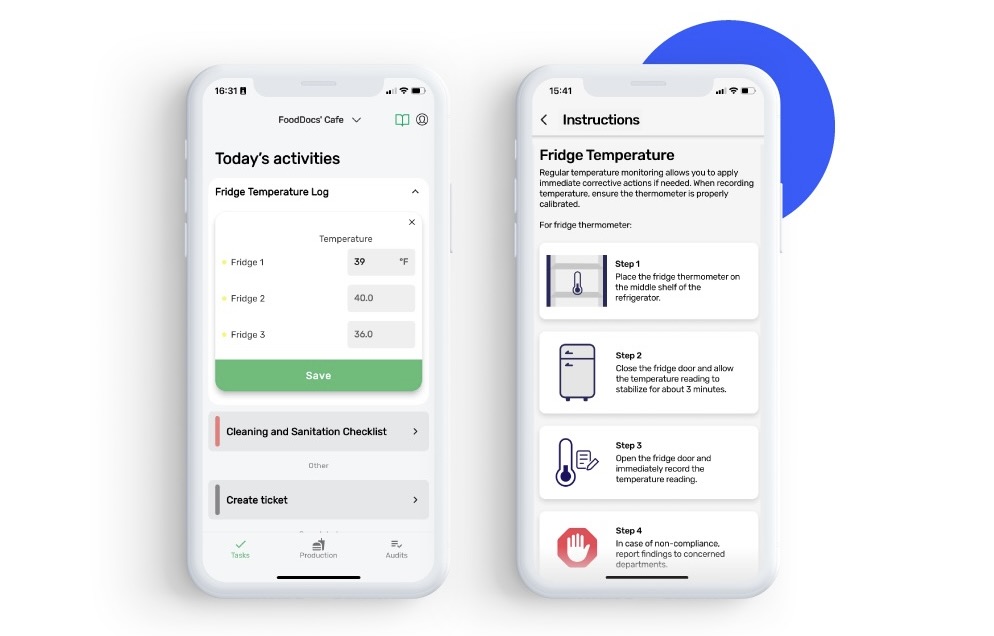

Maintaining the appropriate temperature during the packaging process is crucial for ensuring the safety and quality of PLA packaging. FoodDocs’ smart Food Safety Management System features a temperature log, allowing businesses to record and monitor the temperature of food products before they are packaged using PLA materials. This ensures that the packaging process adheres to the necessary temperature guidelines, preserving the integrity of the PLA packaging and the safety of the food products inside.

Temperature log example:

| Date | Time | Product | Temperature (°C) | Notes |

|---|---|---|---|---|

| 2024-02-25 | 08:00 AM | Salad | 4 | Packaged using PLA tray |

| 2024-02-25 | 12:30 PM | Sandwich | 8 | PLA container used |

| 2024-02-25 | 04:45 PM | Fruit Cup | 3 | PLA cup utilized |

By consistently monitoring and documenting the temperature of food products before packaging, businesses can ensure that PLA packaging is used within the appropriate temperature range, maintaining food safety standards.

Cleaning and Sanitation Checklist to Ensure PLA Packaging is Free from Contamination

Regular cleaning and sanitation of equipment and workspaces are essential for preventing contamination and maintaining the safety of PLA packaging. FoodDocs’ smart system includes a comprehensive cleaning and sanitation checklist, enabling businesses to establish and adhere to rigorous cleaning protocols for equipment used in conjunction with PLA packaging. By following these checklists, businesses can minimize the risk of contamination, ensuring that PLA packaging remains safe for food use.

Cleaning and sanitation checklist example:

- Daily cleaning of 3D printing equipment used for creating PLA packaging;

- Sanitization of storage areas for PLA filament and finished PLA packaging products;

- Weekly deep cleaning of production areas where PLA packaging is handled and stored.

By implementing and consistently following these checklists, businesses can uphold the safety and quality of PLA packaging, meeting stringent food safety standards.

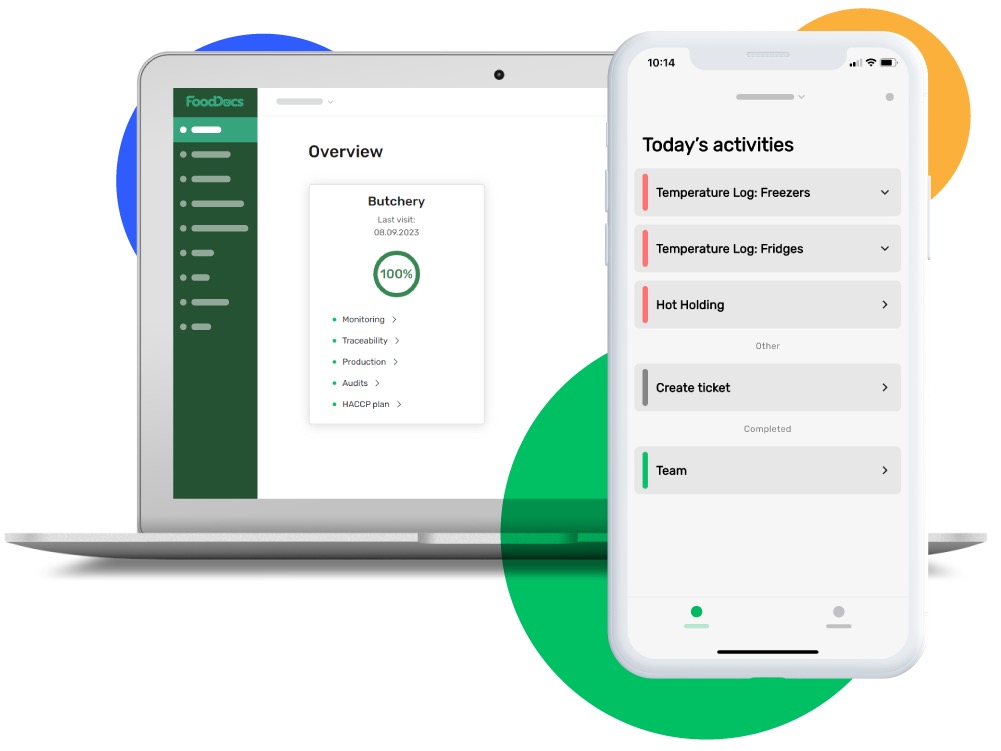

Real-time Dashboard to Identify Areas that Need More Attention

Monitoring and analyzing data in real time is essential for identifying potential issues and areas that require additional attention when using PLA packaging. FoodDocs’ smart system features a real-time dashboard that provides businesses with immediate insights into their PLA packaging processes. By tracking key performance indicators and compliance metrics, businesses can identify any deviations from safety standards and take prompt corrective actions, ensuring the ongoing safety of PLA packaging.

Real-time dashboard metrics:

- Temperature deviations during the packaging process;

- Compliance with cleaning and sanitation protocols;

- Production output and efficiency of PLA packaging processes.

By leveraging the real-time dashboard, businesses can proactively address any concerns related to the safety and quality of PLA packaging, maintaining the highest standards of food safety.

Conclusion

In conclusion, polylactic acid (PLA) presents itself as a safe and environmentally friendly alternative to traditional packaging materials. Its biodegradability, non-toxic nature, and renewable sourcing make it an attractive option for businesses seeking sustainable packaging solutions. When used appropriately, PLA is a viable material for creating food packaging, offering versatility and customization through 3D printing technology.

With the implementation of modern food safety management systems, such as FoodDocs’ smart system, businesses can effectively manage the safety of PLA packaging. Features such as temperature logs, cleaning and sanitation checklists, and real-time dashboards enable businesses to uphold the highest standards of food safety while utilizing PLA packaging in the food industry.

As the demand for sustainable practices continues to grow, PLA stands at the forefront of innovation, providing a pathway towards more environmentally responsible packaging solutions in the food industry. By understanding the properties of PLA, its safe usage, and effective management through modern systems, businesses can confidently embrace PLA as a food-safe packaging material, contributing to a more sustainable future.