3D-printed food, ranging from pasta and chocolate to meat alternatives, is gaining traction in the culinary world. Despite some skepticism towards 3D-printed meat, its presence is increasingly solidified in the market. The shift towards plant-based diets, including vegan, flexitarian, and vegetarian lifestyles, along with concerns over livestock farming, has fueled the demand for meat alternatives that closely mimic the taste and texture of real meat. This article delves into the realm of 3D-printed meat, addressing questions about its nature and production.

What Is 3D-Printed Meat?

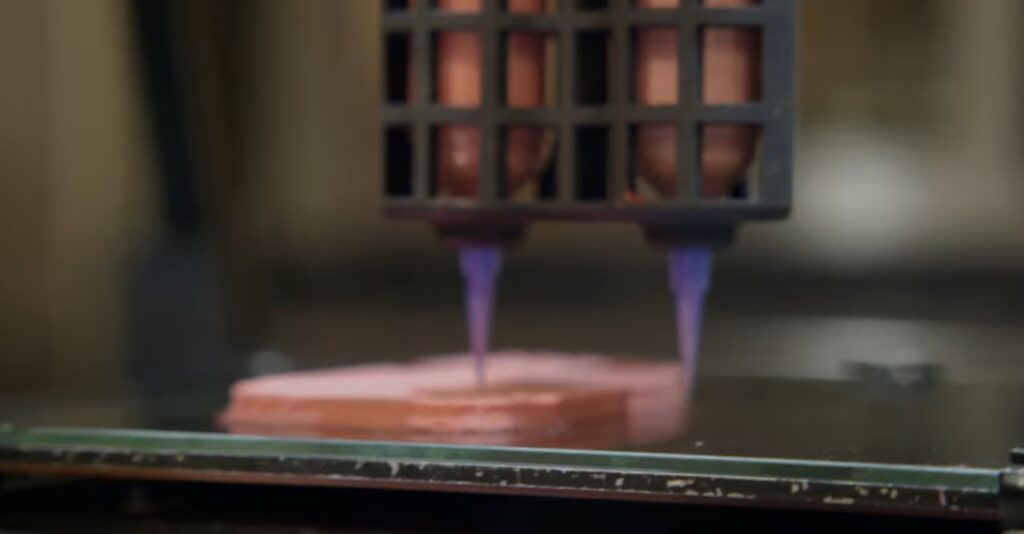

3D-printed meat, a cutting-edge development in the food industry, represents a significant leap toward sustainable and ethical food production. This form of cultured meat leverages sophisticated 3D printing and additive manufacturing technologies, enriched by the analytical prowess of artificial intelligence and the foundational principles of material science. The process distinguishes itself by utilizing cultured animal cells as the ‘ink.’ These cells are meticulously ‘printed’ into forms that mimic conventional meat cuts, offering a novel approach to meat production that diverges from traditional methods.

Unlike conventional printing, this innovative method employs a consumable material to craft edible products, merging technology with culinary artistry. The steps involved in creating 3D-printed meat underscore the technological marvel behind this process:

- Cell Cultivation: The journey begins with the cultivation of animal cells, carefully selected for their suitability in creating the desired meat texture and nutritional profile;

- Material Preparation: These cells are then prepared as the ‘ink,’ a bio-ink to be precise, ready for the printing process;

- 3D Printing: Employing advanced 3D printing technology, the bio-ink is layered to form shapes that closely resemble traditional meat cuts, from steaks to burgers, in a controlled and sterile environment;

- Post-Processing: After printing, the meat undergoes a maturation process to enhance its flavor and texture, ensuring that it closely mimics the sensory and nutritional qualities of conventional meat;

- Cooking: It’s crucial to note that, much like traditional meat, 3D-printed meat requires cooking before it can be consumed. The printing process meticulously shapes the meat, but cooking is necessary to ensure its safety and palatability.

This method not only introduces a sustainable alternative to conventional meat production but also opens doors to unprecedented levels of customization in terms of texture, nutrition, and taste. By significantly reducing the environmental impact associated with traditional livestock farming and offering solutions to ethical concerns, 3D-printed meat stands at the forefront of food technology, promising a future where meat consumption is both conscientious and tailored to individual dietary needs.

Ingredients in 3D-Printed Food

The versatility of 3D printing allows for a wide range of ingredients to be used, adhering to specific printing techniques such as extrusion-based printing and selective laser sintering, among others. Ingredients commonly used in 3D food printing include purees, mashed potatoes, jellies, cheeses, chocolates, sugars, protein powders, and various sauces. For 3D-printed meat, both plant-based components like peas and beetroot and cultured animal cells are utilized.

Production of Cultured Meat

The creation of lab-grown cultured meat begins with the isolation of bovine stem cells or cells from chicken eggs, which are then cultivated in a bioreactor. This process results in a significant amount of biomass, which is subsequently differentiated into muscle and fat tissues. These tissues are then printed into edible forms of meat, ensuring a safe and ethical production method.

Vegetarian and Vegan Considerations

Whether 3D-printed meat is considered vegetarian or vegan depends on the ingredients used. Some variants are made entirely from plant-based sources, while others utilize cultured animal cells. Although using cultured cells does not involve traditional animal farming, some vegetarians and vegans may still have reservations.

Health Benefits and Nutritional Content

3D-printed meats offer several health benefits over traditional livestock meats, including reduced risks of cardiovascular disease, diabetes, and certain cancers. These meat alternatives can be tailored to meet specific dietary needs, offering higher nutritional value without unhealthy fats.

Economic and Environmental Impact

Currently, the high cost of production for 3D-printed meat makes it a less accessible option for many consumers. The technology and materials required are expensive, but as production scales up, prices are expected to decrease. Environmentally, 3D meat printing is more sustainable than traditional meat production, requiring fewer resources and resulting in less waste.

Taste and Texture

Efforts to replicate the taste and texture of real meat using 3D printing technology have been promising, with some products reportedly mirroring the flavor of traditional meats closely. However, widespread acceptance and adoption may be influenced by personal perceptions and the novelty of consuming lab-grown meat.

Future of Alt-Meats

The potential for creating a variety of alternative meats through 3D printing is vast, with options ranging from ground beef and burgers to lamb and sausages. As technology advances, the types and quality of alt-meats available to consumers are expected to expand, offering environmentally friendly and ethical alternatives to traditional meat sources.

The Advantages of Employing 3D Printing for Food Production

The world of culinary arts is witnessing a remarkable transformation with the integration of 3D printing technology, offering numerous benefits and innovative solutions to current challenges.

Customization Capabilities

A primary advantage of 3D printing in food production is the unprecedented level of customization it offers. This innovative technology facilitates the meticulous alteration of a food item’s taste, flavor, texture, and appearance, thereby ensuring a highly personalized eating experience that can cater to the most specific of consumer desires. Such personalization is not just about indulging individual preferences but also about enhancing consumer satisfaction by aligning closely with dietary needs and taste profiles. This ability to tailor food products extends beyond mere novelty; it represents a significant shift towards more consumer-centric food production. By leveraging 3D printing, manufacturers can create unique, customized products that were previously unattainable, making it possible to serve niche markets or address specific health-related dietary restrictions. The implications for personalized nutrition and gastronomy are profound, offering a future where food is not only tailored to taste but also to nutritional requirements, transforming how we think about food preparation and consumption.

Enhanced Nutrition

3D-printed foods are distinguished by their potential to surpass conventional foods in terms of nutritional value. The granular control over the composition of 3D-printed food products allows for the creation of customized nutritional profiles, directly addressing the unique dietary requirements of various consumer groups, including the elderly, athletes, or individuals managing specific health conditions. This capability to fine-tune the levels of proteins, sugars, vitamins, minerals, and fats—together with the option to engineer softer textures for those who may struggle with traditional food textures—presents a revolutionary approach to nutritional science. Furthermore, the precision in nutrient incorporation ensures that each bite of food can be optimized for health benefits, potentially leading to better health outcomes and quality of life for consumers. This aspect of 3D food printing not only caters to the growing demand for personalized nutrition but also aligns with broader public health goals, such as reducing obesity and combating malnutrition, making it a valuable tool in the future of food technology.

Sustainability

In an era where sustainable food production is paramount, 3D printing offers innovative solutions. The technology can utilize alternative protein sources, such as insects, in a more palatable form. For instance, crickets, known for their high protein content and low environmental footprint, can be transformed into a nutritious and sustainable meat alternative through 3D printing. This approach significantly reduces the natural resources required for food production, offering a path toward more sustainable consumption patterns.

Reduction of Food Waste

3D printing technology has the potential to significantly reduce food waste, a pressing global issue. By repurposing consumable ingredients that would otherwise be discarded, such as leftovers or bruised fruits, 3D printing can help address the annual generation of over 1.3 billion tons of food waste.

Consistency and Reproducibility

Achieving consistency in food production is made easier with 3D printing. The technology allows for precise replication of recipes, ensuring that each product, from pancakes to burger patties, meets ideal standards every time.

Space Exploration

The application of 3D food printing extends to space exploration, providing astronauts with nutritious and customizable food options. Unlike traditional freeze-dried food, 3D-printed food offers longer shelf life and the ability to tailor meals to personal tastes, supporting longer-duration space missions.

Why Opt for 3D Printing for Meat Production?

3D-printed meat presents a forward-thinking alternative to traditional livestock farming, addressing several critical issues.

- Reduced Dependence on Livestock. Moving away from livestock farming reduces the environmental impact, notably in terms of greenhouse gas emissions. This shift is crucial in the context of escalating climate change concerns, making 3D-printed meat an attractive option;

- Health Benefits. 3D-printed meat offers significant health advantages by enabling the customization of nutrition profiles, including the precise tailoring of flavor and texture to meet specific dietary needs and preferences. This customization goes beyond mere satisfaction, opening avenues for healthier eating by reducing unwanted fats, enhancing protein content, or incorporating essential vitamins and minerals tailored to individual health requirements. It paves the way for a new era of dietary management, where consumers can enjoy delicious meats designed to support heart health, weight management, or muscle growth, depending on their personal health goals. Moreover, by eliminating the risk factors associated with traditional meat consumption, such as hormones and antibiotics, 3D-printed meat stands as a cleaner, safer alternative that could revolutionize how we approach meat consumption for health and wellness;

- Catering to Diverse Diets. The advent of 3D-printed meat marks a significant milestone in catering to diverse diets, offering a spectrum of vegan, flexitarian, and vegetarian-friendly meat alternatives that convincingly mimic the taste, texture, and nutritional value of traditional meats. This inclusivity addresses the growing demand for plant-based diets, providing a sustainable and ethical option that appeals not only to those abstaining from animal products for ethical or environmental reasons but also to individuals with specific health conditions that limit their meat intake. The ability to produce meat alternatives that can satisfy the palates of even the staunchest meat lovers demonstrates a remarkable advancement in food technology, bridging the gap between dietary preferences and environmental sustainability while promoting inclusivity in dining experiences.

What about De-Animalization of 3D Printing Meat?

The concept of “de-animalization” brought forth by 3D printing technology represents a transformative approach to utilizing animal parts that are conventionally overlooked or discarded. This innovative process not only champions sustainability by minimizing waste but also challenges traditional culinary boundaries, offering a creative solution to the ethical and environmental issues associated with meat consumption. By transforming less desirable cuts and parts into visually appealing and palatable products, 3D printing technology is redefining what is considered edible, pushing the boundaries of culinary innovation. This approach not only respects the animal by utilizing more of it but also introduces a sustainable model that could significantly impact how we consume meat, promoting a more ethical and environmentally conscious food system.

Conclusion on 3D-Printed Meat

Transitioning from an experimental phase to a burgeoning industry, 3D-printed food, especially meat, is poised to address and mitigate the myriad of challenges associated with traditional meat production methods. As this technology continues to evolve, it promises to revolutionize how we think about, produce, and consume food, offering sustainable, nutritious, and customizable eating experiences.