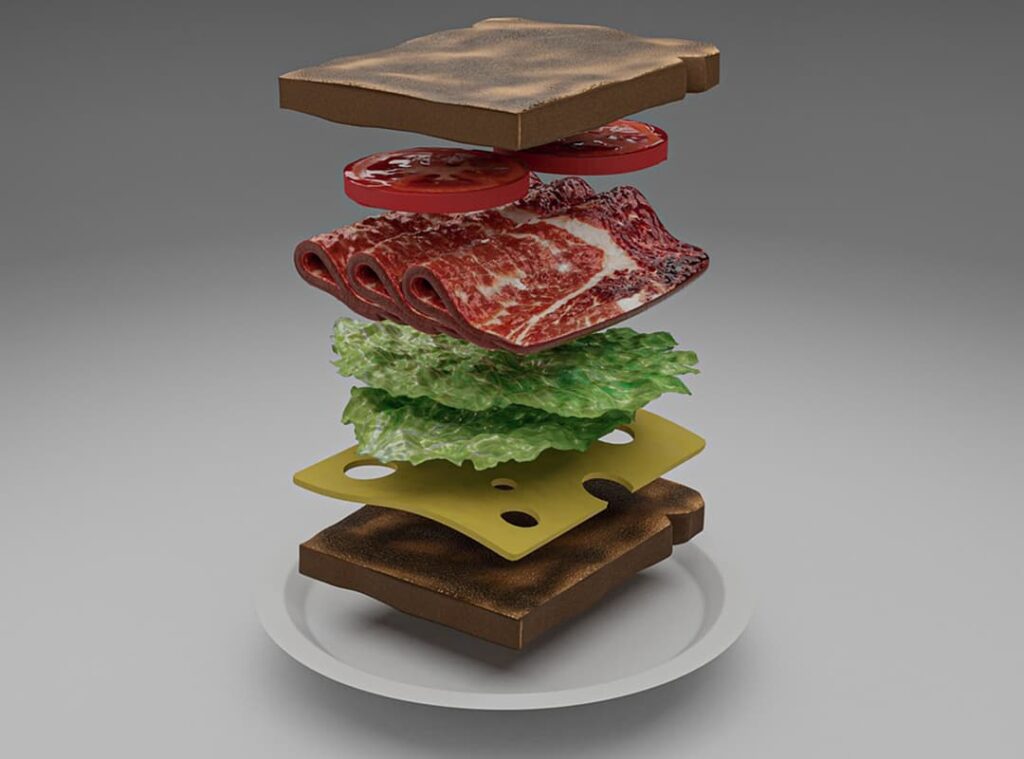

Food is an essential part of human life. However, not everyone can benefit from the rich variety of food available to us. For patients with dysphagia (swallowing problems), mealtimes can be difficult and an alternative to make eating easier must be found. Dysphagia patients suffer from impaired chewing and swallowing, so they need to eat mashed food. Their everyday food is mixed, so it is unrecognizable, tasteless, odorless and unattractive. One of the companies working on a solution is Gastrology, a Dutch firm founded in 2019 by Peter Nieukerk. The company develops 3D-printed food for these patients that is both tasty and visually appealing, aiming to make eating a pleasure by replacing the bland mixed options currently on the market.

Gastrology’s products are 3D-printed food products that are sold in frozen and packaged form. In December 2022, construction of a special production site in Poortvliet, the Netherlands, began. The production process consists of five stages:

- processing (production of puree);

- 3D printing of food products on an industrial scale in an air-conditioned room at temperatures up to 6 degrees Celsius. 3D food printing involves the reservoir of the 3D food printer, which is filled with fresh food puree. After that, the nozzles are efficiently moved by the silicon printing area. The semi-finished product is then applied in a controlled manner, layer by layer, to create a 3D product in one process without the use of any molds;

- shock freezing process;

- packaging in a similar air-conditioned room and deep freezing;

- frozen storage (-20 degrees Celsius). The finished products only need to be heated.

Gastrology works exclusively with 3D food printing technology. Food Lab works with desktop 3D printers for food, and industrial production works with a unique industrial-scale food 3D printer capable of printing 43 kg per hour at the pilot stage. At the scale-up stage, this figure will increase to 130 kg per hour.

The 3D food printing technique allows us to present products in their original form, made from fresh mashed potatoes, with their natural flavor and formed (printed) in their original form. For example, 3D-printed broccoli looks like broccoli, smells like broccoli, tastes like broccoli, but dysphagic patients can eat it with a spoon.